During the design phase of this innovative product, our goal was to create a fixation tack that would be easy to place in any type of bone and capable of securely immobilizing the membranes currently used in GBR (both resorbable and non-resorbable), as well as meshes. Additionally, thanks to its blue coloring, the tack is easy to locate after the designated Bone Regeneration period.

The Supertack tack features a 2.5 mm diameter head, a fairly common size for this type of device. The shaft of the tack has a tapered shape, which allows for quick and easy removal. Moreover, the blue coloring makes it easier to identify under soft tissue during removal.

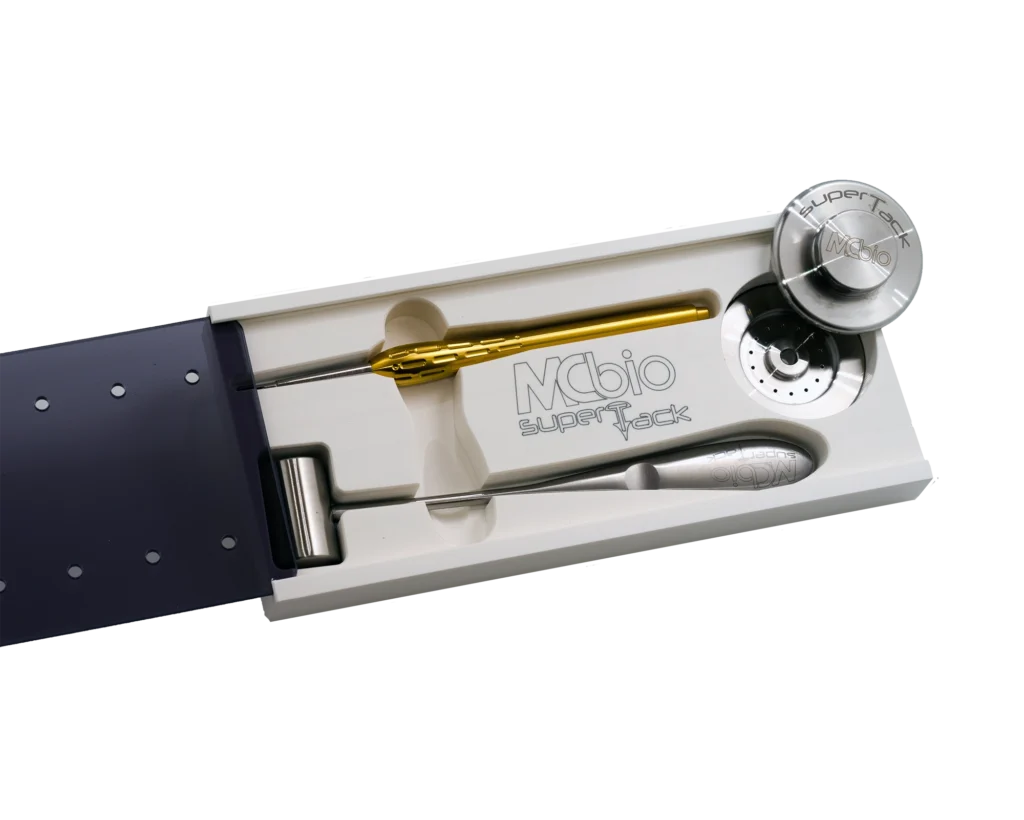

Supertack tacks are packaged in a cleanroom after undergoing plasma surface cleaning. They are sold in a sterile state.